Codapack - Rollerpack - Pre-inked Ink Rollers

Printers are manufactured from robust aluminium castings and roller bearings giving long trouble free life.

The coders are mounted to a conveyor with a simple mounting bracket.

The boxes to mark are led to the marking unit, the printing pressure can be adjusted to suit the strength of the carton and to obtain a perfect print. The print can be made on almost any position of the carton, on top, on the left or on the right side.

Also available for endless printing.

Many standard font styles are available in baselock range, customized print styles, logos and graphics are produced exactly to your requirements.

Codapack - Rollerpack

430-25std, 430-50std, 430-100std

Model displayed 430-25std

Free running unit.

Model 430-25std Printing size - Max charactor 25mm height x 430mm length.

Model 430-50std Printing size - Max charactor 50mm height x 430mm length.

Model 430-100std Printing size - Max charactor 100mm height x 430mm length.

The most reliable Single and multi - line printing machines.

Prints on porous surfaces.

Prints cartons, sacks or continuous material. Top, bottom, side and front marking.

Uses replaceable pre-inked rollers

ROL1 or ROL2.

The printing unit can be set up to code left or right.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Codapack - Rollerpack

430-25id, 430-50id, 430-100id

Model displayed 430-100id with indexed rotation.

Indexed Rotation unit.

Model 430-25id Printing size - Max charactor 25mm height x 430mm length.

Model 430-50id Printing size - Max charactor 50mm height x 430mm length.

Model430-100id Printing size - Max charactor 100mm height x 430mm length.

With an indexed rotation the Codapack / Rollerpack makes an unique printing code mark per carton, which is always printed at the same position.

The printing unit can be set up to code left or right.

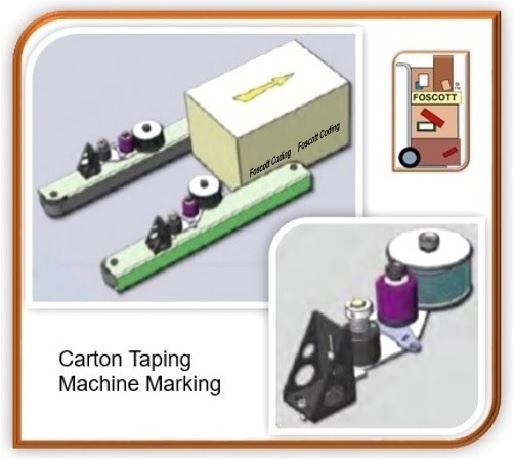

Codapack - Rollerpack

Coders for carton taping machines.

Model 430-25-Tape

Marking size - 25mm width x 430mm length

With an indexed rotation £618.00

Free running unit £516.00

Model 430-50-Tape

Marking size - 50mm width x 430mm length

With an indexed rotation £655.00

Free running unit £549.00

Model 430-100-Tape

Marking size - 100mm width x 430mm length

With an indexed rotation £690.00

Free running unit £582.00

Pre-inked Rolls

Impregnated with ink

Outside diameter 63.5mm (OD)Inside diameter 25.4mm (ID)

ROL1 Black RX

Supplied in tubes of 13 only

Pre-inked rolls are quickly placed on the Codapack, Rollerpack, Hand Roller printer to get a dense quality print on to porous surfaces such as cartons, trays, wood, and paper sacks.

The Plastic-Ink is a plastic micro-porous ink roller through which ink is injected.

The ink roller adapts to varied uses and applications: different dimensions, manual or automatic printing, rapid or slow printing.

Inking through the ink roller remains constant.

The capillarity of the ink roller ensures that the ink does not accumulate at the bottom of the pad (unlike pads made of felt, fibre or foam).

The Plastic-Ink is particularly suited to printing on porous material (paper, cardboard, wood, etc.) on which it dries up instantly through absorption.

It also presents a number of other advantages:

Mounting on all printing apparatus

Excellent results in any position – vertical or horizontal, for printing on sides, on top or on the bottom of packaging.

No handling liquid inks (always a delicate process).

Long-life.

This of course depends on the use – size of text, printing material, printing speed, ink roller dimension, etc…. No evaporation.

The Plastic-Ink does not dry up even during long periods of non-use, and is immediately ready-to-use when production is resumed.

No ink spill or spatter due to centrifugal force during rotation.

No soiling or staining of the characters.

We can also manufacture special pre-inked rollers to your specification - the minimum inside diameter ⌀ we can produce is 10mm.

ROL2

Pre-inked Rolls

Impregnated with ink

ROL2 Black RX

Supplied in tubes of 7 only

Pre-inked rolls are quickly placed on the Codapack, Rollerpack, Hand Roller printer to get a dense quality print on to porous surfaces such as cartons, trays, wood, and paper sacks.

The Plastic-Ink is a plastic micro-porous ink roller through which ink is injected.

Inking through the ink roller remains constant.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

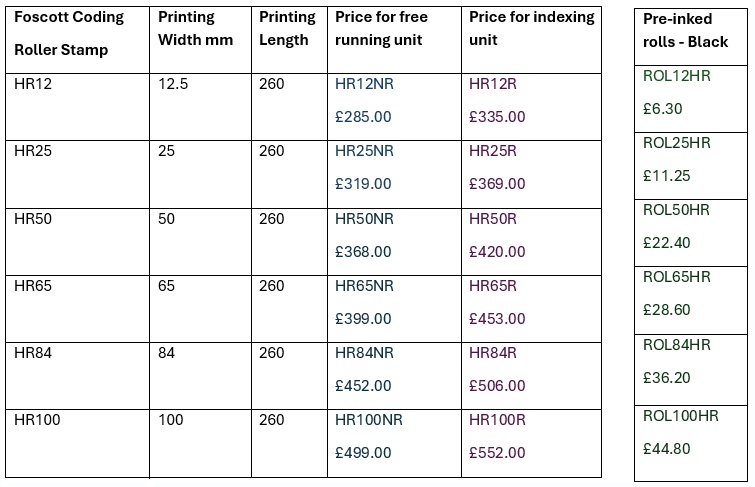

HR25NR

Hand Roller Coder

Free Running Model

Printing width 25mm

Printing length 260mm

Model displayed is the indexed return unit

Made of sturdy aluminium, designed for industrial use.

Flexible rib system using Baselock characters can exchange texts quickly and easily.

The pressure roller is freely movable.

Use for continuous printing.

You can order the roller stamp with the ribbed rubber system and replace your text and logos as desired.

On request, we can stick together your individual logo printing plate to the pressure roller.

Pre-inked plastic ink rollers are very rich ink rollers giving up to 5000 impressions on paper and up to 2500 impressions on wood.

The rollers can be exchanged with a few simple steps.

ROL 1 - 25mm - Black.

£319.00 + Vat

HR50NR

Hand Roller Coder

Free Running Model

Printing width 50mm

Printing length 260mm

Model displayed is the indexed return unit

Made of sturdy aluminium, designed for industrial use.

Flexible rib system using Baselock characters can exchange texts quickly and easily.

The pressure roller is freely movable.

Use for continuous printing.

You can order the roller stamp with the ribbed rubber system and replace your text and logos as desired.

On request, we can stick together your individual logo printing plate to the pressure roller.

Pre-inked plastic ink rollers are very rich ink rollers giving up to 5000 impressions on paper and up to 2500 impressions on wood.

The rollers can be exchanged with a few simple steps.

ROL 2 - 50mm - Black.

£368.00 + Vat

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Please contact us for more models

RC5

Hand Roller Coder

All models are equipped with an indexed rotation system, they can also work continuously.

Drum circumference 350mm

Max length of charactors 240mm

Max width of print 95mm

For use with easily interchangable Baselock letters - numbers.

Or we can make your own logo for printing.

For marking porous substrates only, wood, paper, cardboard, etc..

Use pre-inked rollers.

£449.00 + Vat

Rol96RXB

Pre-inked rollers

Black

For the RC5 Roller Coder.

£20.65 each roller.

Porous substrates ink

for wood, cardboard etc...

Black.

£22.95 + Vat

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------