Overwrapping Machinery / Tray Lidding Machinery

Overwrapping Machinery

Simplicity® Overwrappers

Mantle® Overwrappers

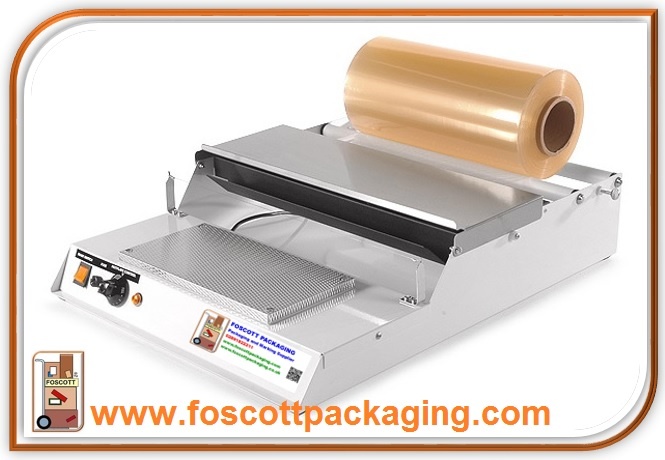

These simple to use hand stretch wrap machines incorporate two support rollers for the stretch film to be used and a stainless steel support bridge that allows the film to pass under the product to be wrapped. The electric console features a constantly heated, low voltage cutting wire to cut the film before sealing the bottom of the tray on the stainless steel hot plate.

The hotplate features adjustable temperature settings.

Simplicity®11 45

Overwrapper

White powder epoxy painted finish.

These simple to use hand stretch wrap machines incorporate two support rollers for the stretch film to be used and a stainless steel support bridge that allows the film to pass under the product to be wrapped. The electric console features a constantly heated, low voltage cutting wire to cut the film before sealing the bottom of the tray on the stainless steel hot plate.

The hotplate features adjustable temperature settings.

Tray Wrapper for use with stretch and cling wrapping films.

With a hot wire cut off.

Quick change cutting wire.

Plastic coated film rollers with friction brake adjustment.

Max film roll : 450mm.

All spares are available from stock.

£246.00 + Vat

Watch our Simplicity® Tray Overwrapper Video

TW45

Mantle® Hand Tray Stretch Over- wrapper

White epoxy painted finish.

For use with food grade stretch films.

These simple to use hand stretch wrap machines incorporate two support rollers for the stretch film to be used and a stainless steel support bridge that allows the film to pass under the product to be wrapped. The electric console features a constantly heated, low voltage cutting wire to cut the film before sealing the bottom of the tray on the stainless steel hot plate.

The hotplate features adjustable temperature settings.

The model TW45 hand stretch wrap machine is a white powder epoxy painted machine.

Choice of easy clean white epoxy paint or stainless steel finish.

Twin roller film holders with adjustable brake.

Quick change cutting wire.

Accepts stretch films up to 450mm wide.

Machine dimensions 660mm x 510mm

Electric 240v

Weight 10kg

All spares are available from stock.

£231.67 + Vat

Stretch films are available in various widths to suit the product to be wrapped, including meat products, vegetables, fish and fruit.

All shrink films for our overwrapping machinery can be viewed in our film page.

Simplicity® 11 45 Stainless Steel

For use with stretch and cling wrapping films.

These simple to use hand stretch wrap machines incorporate two support rollers for the stretch film to be used and a stainless steel support bridge that allows the film to pass under the product to be wrapped. The electric console features a constantly heated, low voltage cutting wire to cut the film before sealing the bottom of the tray on the stainless steel hot plate.

The hotplate features adjustable temperature settings.

With a hot wire cut off.

Quick change cutting wire.

Plastic coated film rollers with friction brake adjustment.

max film roll : 450mm

All spares are available from stock.

£305.00 + Vat

TWS45

Mantle® Hand Tray Stretch Overwrapper

Stainless Steel Finish.

For use with food grade stretch films.

These simple to use hand stretch wrap machines incorporate two support rollers for the stretch film to be used and a stainless steel support bridge that allows the film to pass under the product to be wrapped. The electric console features a constantly heated, low voltage cutting wire to cut the film before sealing the bottom of the tray on the stainless steel hot plate. The hotplate features adjustable temperature settings.

Stretch films are available in various widths to suit the product to be wrapped, including meat products, vegetables, fish and fruit.

The model TWS45 hand stretch wrap machine is a stainless steel machine.

Choice of easy clean white epoxy paint or stainless steel finish.

Twin roller film holders with adjustable brake.

Quick change cutting wire.

Accepts stretch films up to 450mm wide.

Machine dimensions – 660mm x 510mm

Electric - 240v

Weight – 10kg

All spares are available from stock.

£306.67 + Vat

VS300

Tray Lidding Machine - Thermosealer

DIE PLATE VERSION

These stainless steel machines feature adjustable temperature control, PTFE coated non-stick sealing plate, twin roll film supports with guide rings and twin gas spring head lift.The VS300 model is supplied with a die plate custom made for the tray to be sealed, with additional die plates available upon request.

The trays are sealed with either a peelable film or a sealable (welded) film.

The machine is switched on and the required temperature set on the regulator, when the temperature has been reached, the film which is mounted at the back of the machine on two support rollers is pulled over the top of the tray to be sealed which had been placed in the die plate.

The sealing head is then lowered by hand and pressed down to seal the film to the tray, at the same time the film is cut from the main roll.

The sealing head is then raised to the open position and the tray removed.

The VS300 lidding machine will work with all types of sealable food trays and films up to a maximum width of 190mm with a maximum tray length of 250mm.

The VS type of tray sealing machine installations are typically found in supermarkets, local butchers and grocery shops producing ready meals, fresh and cooked meats, fish and vegetables.

Product Features

Adjustable temperature control.

PTFE coated sealing plate.

Stainless steel fabrication.

Twin reel film supports.

Quick change die plates. (No tools required)

VS300

Technical Specifications

Maximum film width - 190mm

Sealing area - 190mm x 250mm

Electric - 240v / 3amp

Machine dimensions - 480 x 255mm

Weight - 9kgs

£786.52 + Vat

VS300DT

Tray Lidding Machine - Thermosealer

ADJUSTABLE BAR VERSION

DIGITAL TEMPERATURE CONTROL

The VS300 lidding machine is available with adjustable bars for use with triangular sandwich wedges. The machine features a set of adjustable bars and a selection of fixed size sealing bars that can be supplied to suit all the usual sandwich wedges available. The peelable type of lidding film is used for sandwiches. The VS type of tray sealing machine installations are typically found in supermarkets, local butchers and grocery shops producing ready meals, fresh and cooked meats, fish and vegetables.

Product Features

Digital temperature control.

PTFE coated sealing plate.

Stainless steel fabrication.

Twin reel film supports.

Adjustable bars to seal sandwich wedges.

VS300DT

Technical Specifications

Maximum film width - 190mm

Sealing area - 190mm x 250mm

Electric - 240v / 3amp

Machine dimensions - 605 x 255mm

Weight - 10kgs

£915.92 + Vat

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------